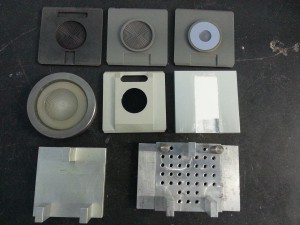

The most common practice in powder XRD is to simply fill the recessed well of a sample holder with finely ground powder and start collecting data. That works for a great many users, but everyone is eventually faced with a more complicated situation at some point. At Texray, odd samples and special requirements are the norm. The photos below represent some of the common and not-so-common needs we’ve come across. Many of these are one-off designs fabricated by KS Analytical Systems.

The top row shows the three most common holders we see with various well depths. These are almost exclusively used for loose powders. The goal is to get the surface of the sample into the plane of diffraction with as little of the holder in the beam as possible. The plastic material has a very high scattering coefficient which creates a hump in the data around 13 degrees 2Theta. These are all designed for the 40-position sample changers from Siemens (now Bruker).

The top row shows the three most common holders we see with various well depths. These are almost exclusively used for loose powders. The goal is to get the surface of the sample into the plane of diffraction with as little of the holder in the beam as possible. The plastic material has a very high scattering coefficient which creates a hump in the data around 13 degrees 2Theta. These are all designed for the 40-position sample changers from Siemens (now Bruker).

The second row gets more interesting with a special holder for high volume instruments. This was designed for magnetic handling and worked great as long as you don’t mind the low angle scatter problem of the plastic and aren’t working with ferrous powders.

The middle is one we use for collecting data from membrane filters. These are notoriously hard to hold down with any precision so they get mounted from the rear and held against a “lip” to keep them both flat, and in the plane of diffraction. They work wonderfully.

Next we have a simple side load sample holder. I’m a big fan of these and use them anytime I’m running loose powders on a single sample stage. It allows the user to load with a very smooth top surface that’s perfectly flat without creating any preferred orientation. Preferred orientation is frequently caused by pressure being applied to the basic top-load holders in an effort to get a flat surface. It is to be avoided whenever possible. Notice that the holders are all Aluminum at this point. Most custom holders are Al or a combination of Al and stainless steel depending upon the special properties desired.

The last row are good examples of odd-shaped sample holders. When you’ve got a rock with one flat surface or a little chip of some material, you still need to keep it in the plane of diffraction. The user simply places a ball of clay in the middle of the holder, the sample goes on top of that and then a glass plate is used to crush the clay (with the sample on top) down such that everything is in plane with the elevates posts. These posts interface with the machine to define the plane of diffraction right across their surface, thus the sample is right where it needs to be without any complicated engineering or microscopic adjustments.

Vacuum holding is common when working with semiconductors or other materials with very consistent thicknesses.

We needed to keep our standards in our desiccator cabinet as well as store membrane filters long-term. Custom laser-cut shelves make this easy.