The D2 Phaser 6-position autosampler uses a completely different sample holder that their other systems. We’ve just completed our first production run of these blanks so they’ll be ready for custom orders. Contact KSA for more information.

The D2 Phaser 6-position autosampler uses a completely different sample holder that their other systems. We’ve just completed our first production run of these blanks so they’ll be ready for custom orders. Contact KSA for more information.

XRD patterns are complicated by a variety of undesirable effects. Some of which are easy to deal with, others are unavoidable. One of the issues we see often is scattering and diffraction effects that are actually being caused by the sample holder itself. These effects can usually be modeled out, but simply knowing which artifacts are being generated from scatter off the sample holder vs amorphous content or phases present in the sample itself can make the difference between an easy analysis and a grinding, iterative march toward a final result. One of the most common effect we see is scatter from plastic sample holders. Most of the sample holders we produce are either Aluminum or PMMA plastic, but either way, one of the easiest ways to avoid undesirable scatter is to simply enlarge the sample well. We’ve been doing this for decades on the standard, non-rotating sample holders by cutting a large, rectangular well rather than the standard, 25mm circular well.

This week we did a little experiment to see just how much larger our sample well needed to be to eliminate the common PMMA hump at ~13 degrees 2Theta (Cu energy). It turns out that an increase of only 5mm in diameter made a huge difference in the total scatter even with very “wide-open” optics. See the scan images below for a real-world picture of the difference we saw. This may not seem like a significant problem until you’re looking for phases with D-spacings down in that region near the hump. Analysis of clay minerals can become particularly complicated. This is a great example of why we love talking to clients and XRD users around the world.

We often receive requests for small powder wells to be ground into our zero-background sample holder plates. I usually try to talk the requestor out of this as it has limited usefulness for most applications, but there are some reasons one might benefit from this type of holder. It’s for these special cases that we’ve always offered custom ground wells in our ZBH plates and we continually improve our process to give our clients exactly what they want and need to get their work done.

There are three reasons I try to avoid this.

One alternative I often recommend is recessing the entire plate by some number of microns to accommodate different particle sizes if that’s a concern. I believe that many XRD users are asking for sample wells in their ZBH simply to avoid the displacement error inherent in mounting their powder on top of a plate which has already been fixed at the plane of diffraction. Recessing the plate allows us to retain the polished surface of the ZBH and allows us to mount it with at least the same degree of precision that a well would provide. Precision mounting adds about as the same cost as grinding, but it definitely has benefits. To my knowledge, KSA is the only company offering this type of mounting.

So that was an awful lot of reasons to avoid this, but there is one very big benefit of using a ZBH with a ground well. This allows you to run very small volumes of sample material while maintaining a very consistent irradiated area. Imagine the same volume of powder spread across a flat plate. Each time this is done, a slightly (if not significantly) different surface area of the plate is likely to be presented. The end result of this will be variations in intensity and perhaps preferred-orientation. Particle statistics change with varying numbers of crystallites in the plane of diffraction as well. This is all complicated by the changes in the irradiated area throughout a normal scan with divergent-beam optics.

The well pictured here is 12mm in diameter and 0.2mm in depth and a good example of the kind of custom work that is most common for us.

XRD sample prep is like a box of chocolates. You never know what you’re going to get… So many materials are fluffy or sticky that even after fine grinding, it’s common to have some clumps that just don’t want to break up. This became a problem for one of our clients using our side-loading tool so they added a piece of mesh to the mouth of the funnel. Their next order included a request for some type of removable solution for this so we mounted some coarse mesh in an acrylic frame that sits nicely on top of the funnel and makes it very easy to sift through sample material as it’s being loaded. We love these so they’ll be an option on all future orders!

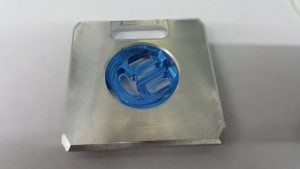

Clay minerology is a fascinating subset of the common powder XRD applications we work with. It seems like every lab has their own unique way of handling the various challenges presented by clays and hence the need for myriad solutions. Most recently we worked with a lab which processes large volumes of clay samples in their various Bruker XRD system and they needed a sample holder that would accommodate their 26 x 26mm glass slides on which their clays are mounted. The solution was a custom holder with a square recess for the plate which is simple enough, but in cases like this, one must take into account the real-world challenges of machining as well as usage. The edges and corners of the glass slides are the least precise part of the plate so the holder has a “moat” around the perimeter to eliminate binding or shifting due to those issues. The center is also relieved as this area does almost nothing to improve precision of the mount, but will cause dramatic displacement errors if any debris gets between the holder and plate in that area.

Clay minerology is a fascinating subset of the common powder XRD applications we work with. It seems like every lab has their own unique way of handling the various challenges presented by clays and hence the need for myriad solutions. Most recently we worked with a lab which processes large volumes of clay samples in their various Bruker XRD system and they needed a sample holder that would accommodate their 26 x 26mm glass slides on which their clays are mounted. The solution was a custom holder with a square recess for the plate which is simple enough, but in cases like this, one must take into account the real-world challenges of machining as well as usage. The edges and corners of the glass slides are the least precise part of the plate so the holder has a “moat” around the perimeter to eliminate binding or shifting due to those issues. The center is also relieved as this area does almost nothing to improve precision of the mount, but will cause dramatic displacement errors if any debris gets between the holder and plate in that area.

These were a little time-consuming to make, but the end result worked beautifully. The client was very happy and we’re happy to have another design to offer to other labs with similar needs.

You can never have enough sample holders no matter what machine you’re running. We’ve certainly found this to be true at Texray so we always try to keep a large number of them on-hand. KS Analytical Systems has always made one-off and custom sample holders for the Bruker instruments, but we’re now offering the standard PMMA powder holders as well at significant cost savings over the OEM version. The standard holder (25mm x 1mm deep well) is priced at $55 with bulk discounts starting at 20 holders.

You can never have enough sample holders no matter what machine you’re running. We’ve certainly found this to be true at Texray so we always try to keep a large number of them on-hand. KS Analytical Systems has always made one-off and custom sample holders for the Bruker instruments, but we’re now offering the standard PMMA powder holders as well at significant cost savings over the OEM version. The standard holder (25mm x 1mm deep well) is priced at $55 with bulk discounts starting at 20 holders.

Custom well depths, diameters, grooved floors, side-loading and zero-background versions are available.

Our PMMA holders are compatible with Bruker D8 Focus – D8 Advance (single, FlipStick autosampler, 90-position autosampler), D4 Endeavor and D2 Phaser (single only) systems. D500 and D5000 instruments can also use these holders.

We’ve brought the complete manufacturing process in-house to give us the freedom to make the custom designs our customer have always asked for. This includes custom laser etching. Company logos are a common request, but we’ve also started serializing sample holders on request. At Texray, we even etch them with barcodes for tracking samples through the data collection process.

The pictures below show a custom funnel tool for filling side-loading sample holders. The tool is machined from billet aluminum with an acrylic window on the funnel to make it easier to gauge fill level. The funnel itself is polished and the viewing plate which allows the users to see when the sample well is full is made of sapphire crystal for maximum scratch resistance.

It’s relatively common for us to receive very small volumes of material for analysis. Often this is the total amount available so getting the right answers is extremely important. When these come in as powders, the answer is always to run them on a zero background plate, but sometimes that’s not the case. Luckily, there are other options for analysis of very small quantities.

It’s relatively common for us to receive very small volumes of material for analysis. Often this is the total amount available so getting the right answers is extremely important. When these come in as powders, the answer is always to run them on a zero background plate, but sometimes that’s not the case. Luckily, there are other options for analysis of very small quantities.

The most common application for filter-membrane sample holders has always been respirable silica quantification. This is mandated by OSHA and is an extremely common industrial hygiene test. Ambient air is sampled with a fixed or mobile suction system and particles are deposited onto a PVC membrane inside a sealed cartridge. Testing procedures are defined by NIOSH7500 and since this is a total quantification method (not a relative method), it’s critical that the entire sample is measured. Unfortunately, the measurement cannot be completed on the PVC membrane as received. Transferring the sample powder to an Ag membrane is accomplished by dissolving or ashing the PVC away, diluting the remainder in a solvent and depositing it onto the Ag membrane by vacuum filtration. The end result is an extremely low loss of analyte even for very small volumes of material.

This preparation method is also very useful for other types of samples which might have crystalline particulate suspended in a solution. Drying samples can be time-consuming, heating them to boil off liquid can cause phase transitions in the crystalline analyte, and handling dry powder in very small quantities is a very good way to lose material. Vacuum filtration solves all these problems.

Our most popular custom sample holder is the SC40F25 which is designed to hold the common 25mm Ag membrane filters used for this type of mounting. The anodized Al body is a time-tested design that works very well and causes almost no interference with the data, unlike the original injection-molded plastic parts. However, the most common method for retaining the membrane has always been to drop a metal support disk behind it and use an ID snap ring to retain both the disk and membrane. This can be a frustrating operation even for experienced hands. Snap rings are hard to control and the high spring tension gouges the inner diameter of the Aluminum body to the point that the holders must be replaced periodically.

Our most popular custom sample holder is the SC40F25 which is designed to hold the common 25mm Ag membrane filters used for this type of mounting. The anodized Al body is a time-tested design that works very well and causes almost no interference with the data, unlike the original injection-molded plastic parts. However, the most common method for retaining the membrane has always been to drop a metal support disk behind it and use an ID snap ring to retain both the disk and membrane. This can be a frustrating operation even for experienced hands. Snap rings are hard to control and the high spring tension gouges the inner diameter of the Aluminum body to the point that the holders must be replaced periodically.

After watching so many clients struggling with this system, we thought we could find a better option. The first step was a simple, laser cut acrylic backer instead of the metal disk. The acrylic was thicker which limited the depth to which the snap ring needed to be set. This was an improvement but still required the snap ring.

The next step was 3D printed plugs which could be pushed into the well. These supported the membrane and held it in the plane of diffraction at the same time. A standard pair of pliers was all the was needed to grab the plug and gently rotated it to release the membrane. This seemed like the ideal solution, but we heard from one user who claimed that the plug was causing an interfering peak in his measurements. We’ve been around the block with 3D printed sample holders in general and it’s definitely true that the common thermoplastics used will crystallize when cooled rapidly. This causes lots of problems for routine analysis of powders, but this was the first we’d heard of a peak being visible through an Ag membrane. Perhaps this user had a particularly thin membrane, but regardless, we needed a new solution, both for their lab and our own.

The next step was 3D printed plugs which could be pushed into the well. These supported the membrane and held it in the plane of diffraction at the same time. A standard pair of pliers was all the was needed to grab the plug and gently rotated it to release the membrane. This seemed like the ideal solution, but we heard from one user who claimed that the plug was causing an interfering peak in his measurements. We’ve been around the block with 3D printed sample holders in general and it’s definitely true that the common thermoplastics used will crystallize when cooled rapidly. This causes lots of problems for routine analysis of powders, but this was the first we’d heard of a peak being visible through an Ag membrane. Perhaps this user had a particularly thin membrane, but regardless, we needed a new solution, both for their lab and our own.

Our current solution is a laser cut “spring” backer which again combines the function of retainer and support in one part. The spring is easy to install by hand and can even be removed by hand, but forceps or needle-nose pliers make this easier. These have been working very well so we’re hopeful that this is going to be a long-term solution that we can share with our clients.

Our current solution is a laser cut “spring” backer which again combines the function of retainer and support in one part. The spring is easy to install by hand and can even be removed by hand, but forceps or needle-nose pliers make this easier. These have been working very well so we’re hopeful that this is going to be a long-term solution that we can share with our clients.

Most of the zero-background sample holders we make are designed with permanently affixed plates. We prefer this dramatically as loose plate are constantly getting dropped, chipped, or lost. However, a permanently affixed plate also gives us the freedom to precisely (within about 0.02mm) set the depth of the plate below the plane of diffraction. This can make a big difference in the results depending upon the volume of powder loaded as the standard “flush mount” puts the plate exactly in the plane of diffraction. This works fine for very small volumes, but it does guaranty the there will be a displacement error of some magnitude regardless of the particle size or volume. For this reason, we always offer custom recessing as an option. The only drawback to the permanently affixed style of mounting is that the offset (or flush mounting height) cannot be changed. Our preferred solution is to simply create a set of holders with various depths to accommodate different sample thicknesses, but we had a request recently for an infinitely variable mounting solution.

Complicating the project is that the holder was to be used in a D2 Phaser with a 6 position autosampler which does not use the same style of base holder as the single-sample variant or any other Bruker XRD that we’re aware of. We discussed several options. The large number of heights needed made multiple holders, spacers, and any other solution that relied on discreet steps unacceptable. The thin-walled sample bases and relatively tight dimensions made a screw-in insert unrealistic as well. The final solution was to build a custom tool for setting the ZBH at a specific depth. This requires the user to work with bare Si plates, but it meets all the design criteria and we’re hopeful that this will work well for them.

The tool is made from acetal (Delrin) plastic which is extremely resistant to chemicals, adhesion, and abrasion. It’s actually an ideal material for threaded parts and machines very well.

I spend a great deal of time meeting with XRD and XRF users throughout the year, but usually in the context of some problem or time-sensitive project. Luckily I’ve been able to attend the Denver X-ray Conference fairly consistently over the last few years. It’s a great time to catch up with other users who are as deeply invested in X-ray spectroscopy and crystallographic analysis as we are. The vendors always put on a great show in the exhibit hall and poster sessions.

The first three days of the week are filled with technical workshops focused on an array of topics. There are always some introductory classes for both XRD and XRF for new users to attend and then there will be additional topics which are usually more advanced. The educational opportunities alone are well worth the attendance fee. Each session is run by an expert in the field and questions, even from industrial users, are welcomed. The sessions are strictly non-sales oriented as well which lends the event a very egalitarian feeling. See the full program here.

Plenary sessions and more sales-oriented meetings occur later in the week and are a great way to get a feel for the cutting edge technology being released by the various vendors. The exhibit hall opens a few days into the conference so everyone has a few days to see all the different booths. We always spend a great deal of time at the Materials Data, Inc and Bruker-AXS booths in particular.

The conference moves between Westminster, CO just North of Denver, Chicago, IL and Big Sky, MT. I’ve never made the trek up to Big Sky, but I hear it’s beautiful. Some attendees only come when it’s up there.

I’d love to connect with as many of our readers as possible so contact us if you’ll be there and I’ll be sure to see you while I’m at DXC-Big Sky!

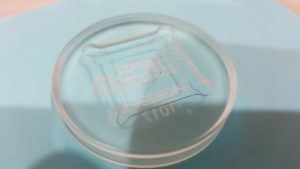

The dreaded “amorphous” hump created by x-rays scattering off plastic sample holders has plagued XRD users for decades. It’s a serious enough problem that we make a good volume of these holders from Aluminum which works very well for loose powders. The plastic scatters xrays at around 13 degrees 2Theta (Cu anode tube) which make a real mess of most geological patterns and isn’t fun to model out for Rietveld refinement. Zero background holders like our ZBH-32 work wonderfully in standard sample stages designed for a single sample at a time, but the large plate isn’t compatible with the autosampler.

I recently had a request for a hybrid holder which would allow for analysis of very small volumes of materials while retaining compatibility with the autosampler. This is almost identical to our standard powder holders, but with a well designed specifically for our small ZBH plate.

Key features include: