MDI Jade has been our goto analysis suite for powder XRD data for decades now. Powerful, versatile, and well supported, it’s earned a following second to none in the industry. What began as a simple suite of MS-DOS-based programs in the early 1990s has blossomed into a full-featured toolset for just about any kind of powder XRD analysis one could need. As computer hardware and software platforms evolved, Jade grew right alongside them with more powerful features, faster processing, and even greater flexibility.

Several years ago it became apparent that the core programming of Jade was going to become a limiting factor in its development. Enter Jade 2010. Built from scratch on next-generation architecture, Jade 2010 freed up the developers at MDI to implement many of the changes they’d been wanting to add for several years. The result was a beautiful new interface with streamlined and reorganized menus that greatly improved the user experience. The new structure allowed for much more integration between features that had once been modular, making them easier to use as well as more powerful. The original Jade suite (now on version 9.8) became Jade Classic and it became clear that there was a sunset coming for the venerable program. The only complaint we ever received about Jade 2010 was that it was only available as an annually-licensed product. Each year the users would need to renew their subscription to continue using the software. This gave me pause just as it did many of our clients, but the rapid pace of development almost necessitated this as new changes and updates were taking place monthly rather than yearly as they had in the past.

Fast forward a few years and we’ve had another big change. Jade Classic (9.8) has been discontinued and Jade 2010 has become Jade Pro. It’s still all-inclusive with all the advanced capabilities available on every license. It’s also still an annually licensed program. Development will continue free from the limitations of the old core programming and the distraction of maintaining two completely separate products.

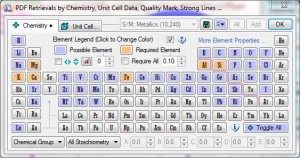

This alone wouldn’t be such big news, but there is a new option that we’ve been waiting for years to see. Jade “Standard”. We now have four additional products available to users with more limited needs and budgets.

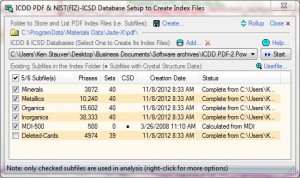

Jade Standard level 1 includes all the basic pattern analysis and manipulation tools that users would need for many of the more common projects as well as some of the more advanced features that were only offered on the premium Jade+ (plus) program before.

Jade Standard level 2 includes all the level 1 functionality, plus Search/Match (2a) or Whole Pattern Fitting/Rietveld (2b).

Jade Standard level 3 includes both Search/Match and Whole Pattern Fitting.

All Jade Standard products are perpetually licensed (One-time purchase, lifetime license).

Several of the ancillary tools offered by MDI are still available as always including Ruby, ClaySim, and RIQAS.

We’ve been waiting a very long time to be able to make this announcement and I must say that the way this has been implemented couldn’t be better for ourselves or our clients.

Please contact KS Analytical Systems for more information and upgrade pricing.