You can never have enough sample holders no matter what machine you’re running. We’ve certainly found this to be true at Texray so we always try to keep a large number of them on-hand. KS Analytical Systems has always made one-off and custom sample holders for the Bruker instruments, but we’re now offering the standard PMMA powder holders as well at significant cost savings over the OEM version. The standard holder (25mm x 1mm deep well) is priced at $55 with bulk discounts starting at 20 holders.

You can never have enough sample holders no matter what machine you’re running. We’ve certainly found this to be true at Texray so we always try to keep a large number of them on-hand. KS Analytical Systems has always made one-off and custom sample holders for the Bruker instruments, but we’re now offering the standard PMMA powder holders as well at significant cost savings over the OEM version. The standard holder (25mm x 1mm deep well) is priced at $55 with bulk discounts starting at 20 holders.

Custom well depths, diameters, grooved floors, side-loading and zero-background versions are available.

Our PMMA holders are compatible with Bruker D8 Focus – D8 Advance (single, FlipStick autosampler, 90-position autosampler), D4 Endeavor and D2 Phaser (single only) systems. D500 and D5000 instruments can also use these holders.

We’ve brought the complete manufacturing process in-house to give us the freedom to make the custom designs our customer have always asked for. This includes custom laser etching. Company logos are a common request, but we’ve also started serializing sample holders on request. At Texray, we even etch them with barcodes for tracking samples through the data collection process.

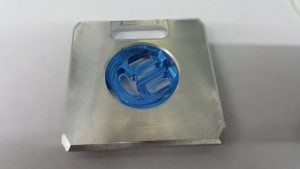

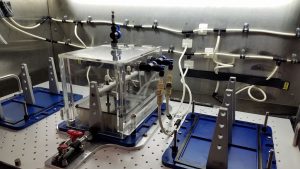

The pictures below show a custom funnel tool for filling side-loading sample holders. The tool is machined from billet aluminum with an acrylic window on the funnel to make it easier to gauge fill level. The funnel itself is polished and the viewing plate which allows the users to see when the sample well is full is made of sapphire crystal for maximum scratch resistance.