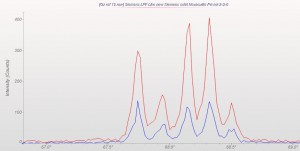

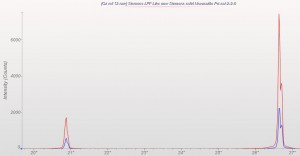

One of the fundamental facts of lab-based X-ray production is that our x-ray tubes emit much more than the pure KA1 lines we rely on for material characterization and quantification. Most XRD users are familiar with techniques and hardware for the reduction or elimination of KB1, W LA1 and Bremsstrahlung, but take for granted the inseparable pair of KA1 and KA2 (referred to as the “doublet”). Luckily for us, these energies are present in strict proportion such that we can factor their paired presence into most XRD analysis to the point that one might barely notice their effect. However, the fact remains that we will see peak broadening at lower angles and completely independent additional peaks at higher angles due to this superfluous discrete emission.

Separating the doublet cannot be accomplished electronically or through absorption/attenuation such as might be effective for KB1 energies. It must be done in the primary-beam with an additional diffraction event. Primary-beam monochromators are generally classified by the number of diffraction events required for a photon to pass completely through the device. Single-bounce, 2-bounce and 4-bounce geometries are common with the latter providing the best energy resolution allbeit the lowest intensity (photon flux). My limited experience suggests that while the single-bounce models retain enough intensity to have some application in powder XRD, the others are relegated to HR-XRD applications such as XRR.

The alignment for any of this hardware is not for the faint of heart as it begins with coarse adjustments using fluorescent screens in the beam path. This was essential for us given how dramatically misaligned the monochromator had become after so many attempts to bring it back into operation. We actually needed our SDD system to verify that we were tuning for Cu KA1 energy rather than the KB1 emissions because some of the most basic aspects of the alignment had pushed way beyond their intended position.

Along the way we built ourselves a motorized remote adjustment tool which we’ll return to the user as small adjustments are required on a regular basis with this kind of monochromator to retain maximum intensity. It’s quite useful and even versatile enough to allow for the adjustment of multiple control knobs.

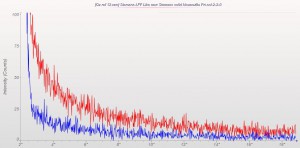

One final note regarding intensity. It’s easy to get excited about energy resolution like this, but bear in mind that we’re looking at ~20x reduction in intensity due to the inherent losses involved in the primary diffraction event. This data was collected at 10x the normal speed and at half the normal 2Theta step increment so it looks very good, but one would need a compelling reason to slow their data collection this much.

Another side effect of performing your energy discrimination in the primary beampath is that other issues such as fluorescence effects (incident x-rays exciting elements in the sample causing high background intensities) are harder to avoid than they would be with a diffracted-beam monochromator. The 4x reduction in intensity inherent in the diffracted-beam monochromatization makes it a poor choice to eliminate these effects when the incident intensities are already so low. We recommend energy-dispersive detectors such as our SDD-150 to eliminate extraneous energies without sacrificing net intensity. We’ve also worked with the Bruker LynxEye XE-T detector which has a very high energy resolution compared to other position sensitive detectors (PSD). Contact KS Analytical Systems for more information on these options.